-

Silica sand, also known as quartz sand, white sand, or industrial sand, consists of two main elements: silica and oxygen. Specifically, silica sand is composed of silicon dioxide (SiO2).

-

Although quartz typically tends to be white or transparent, it comes in a wide spectrum of colors. The color of sand deposits largely depends on the types of minerals and rock sediments that comprise it.

-

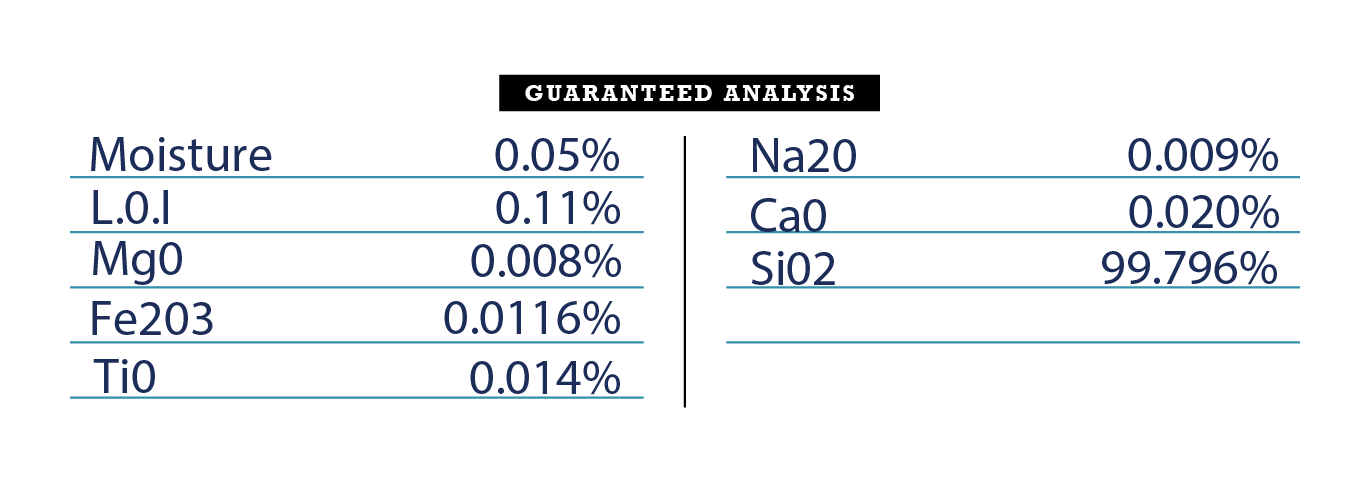

To be classified as silica sand, the material should contain a minimum of 95% silicon dioxide and less than 0.6% iron oxide. If the sand does not meet these conditions, it is known as ordinary sand.

Uses of silica sand

Silica sand constitutes an important element in the glassmaking industry, where silicon dioxide serves as the primary component for various glass products such as windows and bottles. The high purity of the silica sand used contributes to determining the final quality of the glass in terms of hardness, clarity, and color.

Silica sand is used in paints and coatings to enhance overall appearance and durability. Silica improves the paint's ability to resist color changes and dirt due to its filler properties. With silica sand's oil absorption characteristics, it produces a long-lasting, pigment-rich, and corrosion-resistant coating.

Silica sand is used to enhance both golf courses and sports fields.

The use of silica sand in water filtration is one of its primary applications, whether for purifying well water or ordinary drinking water. Due to its uniform shape and size, silica sand forms an excellent filtration layer that efficiently removes contaminants from water. Additionally, it does not degrade when exposed to acidic substances.

Silica plays a central role in shaping the glaze of all ceramic forms, including pottery, floor tiles, and wall tiles. As the structural basis of ceramics, silica contributes to controlling expansion and contraction during drying, ensuring high quality and greater durability of ceramic products.

Silica sand is commonly used as an abrasive agent. Although its use can generate potentially hazardous dust, exposure to this dust can be mitigated by following recommended personal protective guidelines and/or using special solutions that minimize dust dispersion.

AR

AR